Identifying the Top and Emerging Automated Plate Handlers Market Trends

The future of laboratory automation is being actively shaped by a set of powerful and innovative Automated Plate Handlers Market Trends that are focused on making these robotic systems smarter, more versatile, more compact, and easier to use. These trends are not incremental improvements; they are a direct response to the evolving needs of modern research and diagnostic laboratories, which are becoming more dynamic, data-intensive, and resource-constrained. The market is moving away from large, monolithic, and inflexible automation systems towards more agile and accessible solutions. The vendors who are successfully identifying and capitalizing on these trends are the ones who are setting the pace for the industry's future, transforming automated plate handlers from a tool for specialists into an accessible and indispensable part of the modern laboratory for a much broader range of scientists.

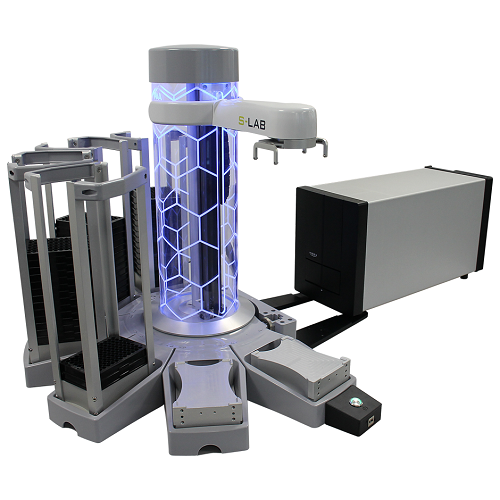

One of the most significant and commercially impactful trends is the drive towards miniaturization and the development of compact, benchtop systems. While large, floor-standing robotic systems are still required for massive HTS facilities, there is a huge and growing demand for smaller, more affordable plate handlers that can fit within a standard biosafety cabinet or on a crowded lab bench. This trend is about "decentralizing" automation. These compact "plate servers" or "stackers" are designed to automate a single instrument, such as a plate reader or a liquid handler, providing a simple "load-and-go" solution. This makes automation financially and physically accessible to a much wider range of laboratories, including smaller academic labs or R&D groups that do not have the budget or space for a large, integrated system, dramatically expanding the total addressable market.

Another dominant trend is the intense focus on increasing the flexibility and versatility of the hardware. Modern research is dynamic, and laboratory needs can change from one project to the next. In response, vendors are designing a new generation of plate handlers that are far more adaptable than their predecessors. A key aspect of this trend is the ability to handle a wider variety of labware beyond standard microplates. This includes deep-well plates, tube racks, tip boxes, and even petri dishes. This is often enabled by the development of intelligent, interchangeable grippers that can be easily swapped out by the user to accommodate different tasks. The ability to quickly and easily reconfigure a robotic system to perform a new workflow without requiring a visit from a service engineer is a major trend that provides a much higher long-term return on investment for the customer.

Finally, perhaps the most critical trend is the relentless focus on improving the software and the overall user experience (UX). In the past, programming a robotic system often required specialized knowledge of a complex scripting language, limiting its use to dedicated automation engineers. The major trend now is the development of highly intuitive, graphical user interfaces (GUIs) that use simple drag-and-drop or point-and-click methods to allow bench scientists to easily set up and run their own automation protocols. This "democratization" of automation is a game-changer. Complementing this is a strong push towards more open software architectures and the provision of robust Application Programming Interfaces (APIs). This allows for easier and more seamless integration with third-party instruments and, crucially, with a laboratory's central LIMS or ELN software, which is essential for creating a truly integrated and data-driven automated laboratory environment.

Explore Our Latest Trending Reports:

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness